Latest news and media

Embroidery, Fashion, High-Tech Inspiration Day

What do Lady Diana's dress, a Victoria's Secret bra, and a high-tech drone have in common?

Find out more![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/f/6/csm_Aerospace_Defense_Meeting_Sevilla_Biontec_Exhibitor_5156e8e7e3.jpg)

Aerospace and Defense Meetings Sevilla

Experience the future of aerospace and defense firsthand as we converge at the Aerospace and Defense Meetings Sevilla – where […]

Find out more![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/a/3/csm_BIONTEC_JEC_World_24_97d8522a5d.png)

JEC World 2024

JEC World gathers the whole value chain of the composite materials industry in Paris every year and is “the place to be” for […]

Find out more

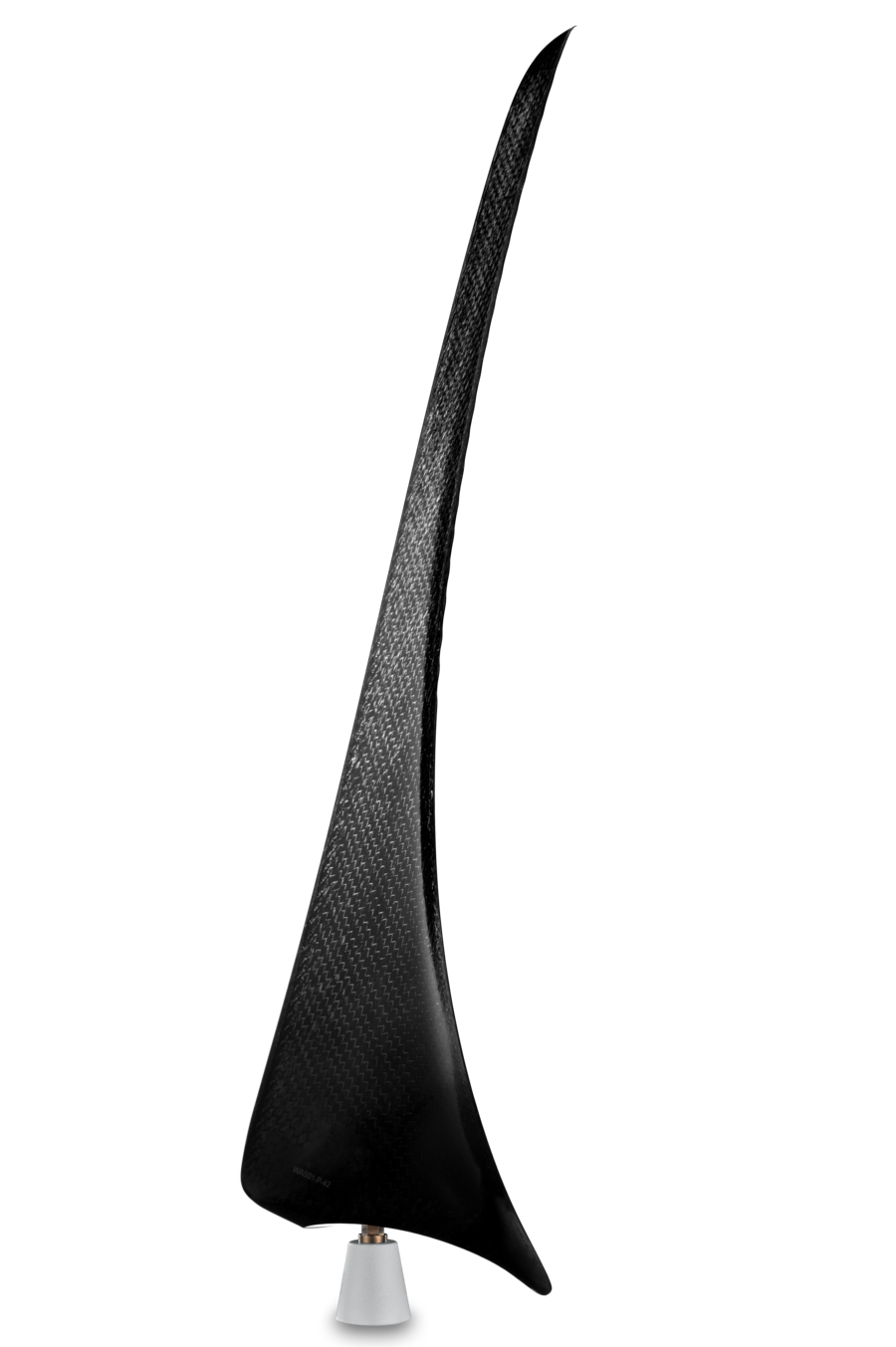

From haute couture to high-tech: Our journey to the automated series production of composite products began with the traditional St Gallen embroidery of the 19th century. Today we develop and produce innovative moulded parts. Bionic. Made of carbon. Efficient lightweight construction, just like you find in nature.